The NormandyFlowChem platform has a large range of modular, versatile and state-of-the-art equipment including "all-in-one" flow chemistry systems, in-line/on-line analysis devices and a wide range of pumps and accessories. Thereby, each reaction is conducted with the appropriate combination of equipment.

« All-in-one » flow chemistry systems

These systems include reagent distribution (pumps) and reaction conditions controle (temperature, activation method...)

CORNING AFR G1 SiC

- Three liquid dosing lines, including one PTFE (max 100 mL/min each)

- One gas dosing line

- 10 silicon carbide plate reactors of 9 mL with patented design allowing very efficient mixing and heat transfer

- Reaction temperature from - 40 to 200 °C

- Kilolab/pilot scale transposition

- FDA and cGMP compliant

Corning AFR LabPhotoReactor

- Two HPLC pumps (max 10 mL/min each)

- One gas dosing line

- 2.7 mL glass plate reactor with patented design for very efficient mixing and heat transfer

- Reaction temperature from -40 °C to 200 °C

- Irradiation to 365, 385, 405, 475 and 610 nm

VAPOURTEC R-SERIES R2S

- Two peristaltic pumps with high chemical compatibility (max 10 mL/min each)

- 4 spots for temperature regulated reactors (from -20 to 250 °C)

- Compatible with Vapourtec photochemistry and electrochemistry modules

- Automation possible

VAPOURTEC RS-300 R2C/R2S

- Two HPLC pumps (max 10 mL/min each)

- Two peristaltic pumps with high chemical compatibility (max 10 mL/min each)

- 4 spots for temperature regulated reactors (from -20 to 250 °C)

- Compatible with Vapourtec photochemistry and electrochemistry modules

- Automation possible

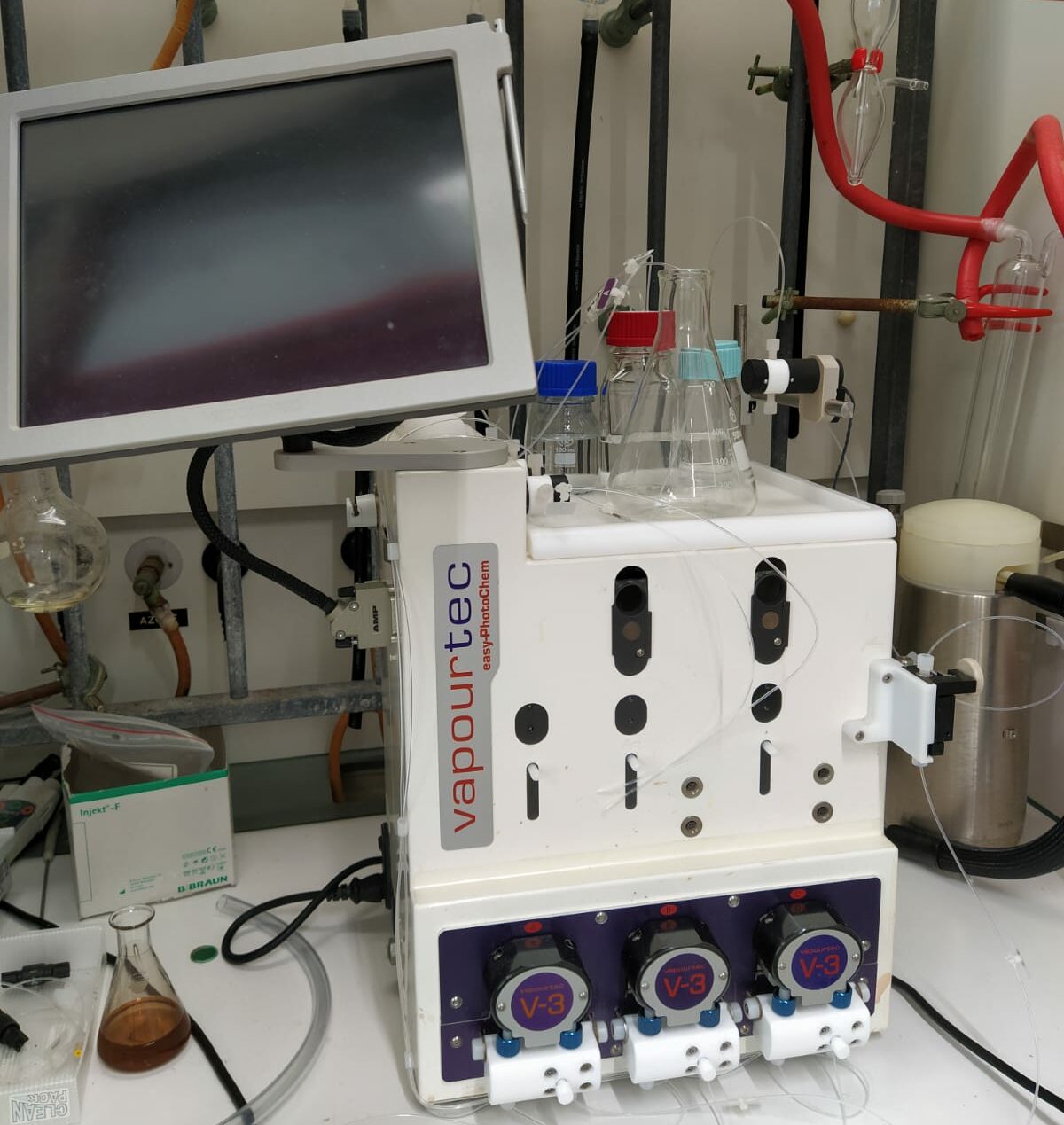

VAPOURTEC E-SERIES

- Three peristaltic pumps with very good chemical compatibility (max 10 mL/min each)

- 3 spots for temperature regulated reactors (from -20 to 150 °C)

- Compatible with Vapourtec photochemistry and electrochemistry modules

In-line/On-line analysis

These devices enable real-time monitoring and analysis of flow processes (conditions stability over time, reaction monitoring, short lifetime reaction intermediates observation...) but also potential auto-optimisation of reaction conditions.

MAGRITEK SPINSOLVE ULTRA X 80

- NMR analysis for 5 nuclei: 1H, 13C, 19F, 31P, 7Li

- 1D and 2D experiments (H-H, H-C, H-F, C-P)

- Solvent signals suppression

- In-line/On-line monitoring

- Automation possible

METTLER TOLEDO REACTIR 15

- Compatible with low temperatures and corrosives conditions

- Good temporal resolution

- In-line/On-line monitoring

- Automation possible

Additionnal equipment

Flow chemistry processes can be achieved with all-in-one systems, assembly of stand-alone modules, or combination of all these elements.

Pumps

- 4 Syrris Asia continuous syringes pumps

- 3 Flom UI HPLC pumps including one with max 100 mL:min flowrate

- 1 Vapourtec SF-10 peristaltic pump

- 17 Harvard Apparatus PhD Ultra syringes pumps

- 3 Harvard Apparatus Elite 11 syringes pumps

- 3 Chemyx F6000X syringes pumps

- Several Bronkhorst gas mass-flow controller (MFC)

Corning Low-Flow skid with 4 glass plates reactors and two temperature zones

Vapourtec UV-150 photoreactors with appropriate lamps:

- Low Pressure Hg UVC 254 nm

- Low Pressure Hg UVB 310 nm

- Low Pressure Hg UVA 370 nm

– LED 365 nm

– LED 405 nm

– LED 430 nm

– LED 450 nm

– LED 470 nm

– LED 525 nm

– LED CW

Vapourtec Ion electrochemistry module

IKA Electrochemical reactor